SHELL APPROVED ‘FE’ TESTING

One of the larger global valve distribution companies contacted Ventil Engineered Solutions team with the request to design and deliver a Fugitive Emission test facility for their West-Europe support centre. The population of valves, intended for volatile air pollutants and hazardous fluids, which are subjected to ‘FE’ testing is growing fast. This applies for new, modified and repaired valves. Subcontracting is possible, but in-house testing turned out to be very cost effective.

Being a global supplier means that they have to have the ability to comply to a variety of test standards and codes, like for example, ISO-15848, Shell SPE 77/312, API 622 and API 624.

After a quick study of the workload and expectations, the Ventil Engineered Solutions team prepared a plan.

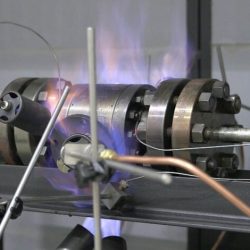

An older Ventil test unit, already present at the clients works, was converted and upgraded. The hydraulic controlled clamping system enables quick position and clamping of the complete range of valves.

The gas test system was modified for the use of the tracer (test) gas Helium.

A mass spectrometer (Shell approved) leak detector was supplied.

A dedicated test area was created to ensure stable test conditions.

An older Ventil test unit, already present at the clients works, was converted and upgraded. The hydraulic controlled clamping system enables quick position and clamping of the complete range of valves.

The gas test system was modified for the use of the tracer (test) gas Helium.

A mass spectrometer (Shell approved) leak detector was supplied.

A dedicated test area was created to ensure stable test conditions.

An important part of delivery was training of the staff and operators. The practical course learned the team to;

- Understand the background, application and requirements

- Select and apply the different test standards

- Understand test criteria and conditions

- Understand leak rates and volumes

- Use of tracer gases and leak detection methods

Get in touch

Do you have questions about a certain project or you have a similar challenge in hands?

Get in touch with the Ventil Engineered Solutions team.

PARTNERS