The STS metric bolt tensioner range is designed for topside operation in a wide variety of applications including pipeline flanges, heat exchangers, pressure vessels, compressor covers, boiler feed pumps, anchor bolts and many others. The range comprises of 32 metric size options ranging from M16 to M100 thread size and all models are suitable for working pressures up to 1500 bar. Each model of hydraulic tensioning cylinder within the tensioner range can be operated with a variety of threaded pullers and nut rotating sockets ensuring that the maximum possible range of bolt sizes can be accommodated using the minimum number of hydraulic cylinders. Threaded pullers and nut rotating sockets are available as individual components.

All Hi-Force hydraulic bolt tensioners are designed and manufactured to include a wear coated piston, maximum piston stroke indicator, self-energising high pressure seals, dual quick connect couplings for easy multiple tensioner connection and a user friendly operation and maintenance procedure.

- Capacities from 234 to 2649 kN

- Bolt sizes from M16 to M100

- Working pressure 1500 bar

- Single acting design with manual piston retraction

- High grade alloy steel construction

- Nitrocarburised piston

- Maximum piston stroke indicator

- Dual quick connect couplings for easy connection

- Designed to fit most sizes of ANSI and API flanges and some Compact flanges

- Interchangeable accessories to cover multiple stud bolt sizes using same tensioner

- Customised and special design tensioners are available on request

| Model number | Bolt Thread Size | Thread pitch | Capacity | Effective area cm2 | Stroke mm | Weight kg | |

|---|---|---|---|---|---|---|---|

| kN | tonnes | ||||||

| STS1-M16B1 | M16 | 2 | 234 | 23.9 | 15.6 | 10 | 1.7 |

| STS1-M18B1 | M18 | 2.5 | 234 | 23.9 | 15.6 | 10 | 1.7 |

| STS1-M20B1 | M20 | 2.5 | 234 | 23.9 | 15.6 | 10 | 1.7 |

| STS1-M22B2 | M22 | 2.5 | 234 | 23.9 | 15.6 | 10 | 1.9 |

| STS1-M24B2 | M24 | 3 | 234 | 23.9 | 15.6 | 10 | 1.9 |

| STS1-M27B2 | M27 | 3 | 234 | 23.9 | 15.6 | 10 | 1.9 |

| STS2-M30B1 | M30 | 3.5 | 457 | 46.6 | 30.5 | 15 | 3.5 |

| STS2-M33B1 | M33 | 3.5 | 457 | 46.6 | 30.5 | 15 | 3.5 |

| STS2-M36B1 | M36 | 4 | 457 | 46.6 | 30.5 | 15 | 3.5 |

| STS2-M39B1 | M39 | 4 | 457 | 46.6 | 30.5 | 15 | 3.5 |

| STS3-M42B1 | M42 | 4.5 | 822 | 83.8 | 54.8 | 15 | 6.1 |

| STS3-M45B1 | M45 | 4.5 | 822 | 83.8 | 54.8 | 15 | 6.1 |

| STS3-M45B2 | M45 | 4.5 | 822 | 83.8 | 54.8 | 15 | 6.3 |

| STS3-M48B1 | M48 | 5 | 822 | 83.8 | 54.8 | 15 | 6.1 |

| STS3-M48B2 | M48 | 5 | 822 | 83.8 | 54.8 | 15 | 6.3 |

| STS3-M52B2 | M52 | 5 | 822 | 83.8 | 54.8 | 15 | 6.3 |

| STS4-M48B1 | M48 | 5 | 1264 | 128.9 | 84.3 | 15 | 10.6 |

| STS4-M52B1 | M52 | 5 | 1264 | 128.9 | 84.3 | 15 | 10.6 |

| STS4-M52B2 | M52 | 5 | 1264 | 128.9 | 84.3 | 15 | 11.8 |

| STS4-M56B2 | M56 | 5.5 | 1264 | 128.9 | 84.3 | 15 | 11.8 |

| STS4-M60B2 | M60 | 5.5 | 1264 | 128.9 | 84.3 | 15 | 11.8 |

| STS4-M64B2 | M64 | 6 | 1264 | 128.9 | 84.3 | 15 | 11.8 |

| STS5-M64B1 | M64 | 6 | 1833 | 186.9 | 122.2 | 15 | 16.0 |

| STS5-M68B1 | M68 | 6 | 1833 | 186.9 | 122.2 | 15 | 16.0 |

| STS5-M72B1 | M72 | 6 | 1833 | 186.9 | 122.2 | 15 | 16.0 |

| STS5-M76B1 | M76 | 6 | 1833 | 186.9 | 122.2 | 15 | 16.0 |

| STS6-M76B1 | M76 | 6 | 2649 | 270 | 176.6 | 15 | 23.5 |

| STS6-M80B1 | M80 | 6 | 2649 | 270 | 176.6 | 15 | 23.5 |

| STS6-M85B1 | M85 | 6 | 2649 | 270 | 176.6 | 15 | 23.5 |

| STS6-M90B1 | M90 | 6 | 2649 | 270 | 176.6 | 15 | 23.5 |

| STS6-M95B3 | M95 | 6 | 2649 | 270 | 176.6 | 15 | 29.1 |

| STS6-M100B3 | M100 | 6 | 2649 | 270 | 176.6 | 15 | 29.1 |

Note: Weight is for load cell and bridge only. Total weight of complete assembly depends on size of puller and nut rotating socket selected. Tommy bars are not included. Hi-Force recommends one tommy bar for every four tensioners.

TOMMY BAR

| Tensioner Range | Tommy Bar |

|---|---|

| STS1 | TTB06 |

| STS2 | TTB08 |

| STS3 | TTB10 |

| STS4 | TTB10 |

| STS5 | TTB14 |

| STS6 | TTB14 |

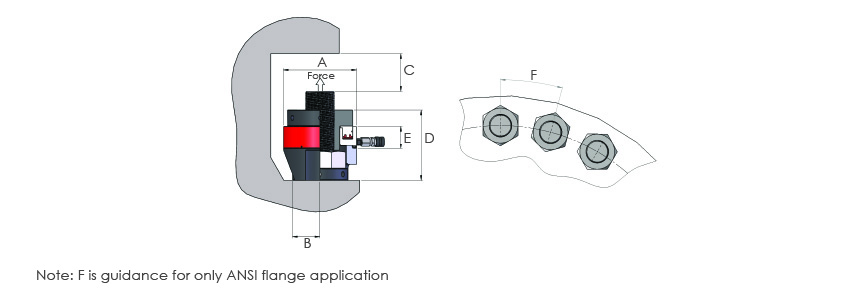

| Model Number | Dimensions in mm | |||||

|---|---|---|---|---|---|---|

| A | B | C min | D | E | F | |

| SBT2-M30B1 | 102 | 39 | 132 | 164 | 91 | 71 |

| SBT2-M33B1 | 102 | 39 | 127 | 164 | 91 | 74 |

| SBT2-M36B1 | 102 | 39 | 123 | 164 | 91 | 77 |

| SBT2-M39B1 | 102 | 39 | 123 | 164 | 91 | 80 |

| SBT3-M42B1 | 137 | 47 | 145 | 188 | 94 | 91 |

| SBT3-M45B1 | 137 | 47 | 142 | 188 | 94 | 105 |

| SBT3-M45B2 | 137 | 47 | 147 | 193 | 94 | 97 |

| SBT3-M48B1 | 137 | 47 | 139 | 188 | 94 | 105 |

| SBT3-M48B2 | 137 | 47 | 144 | 193 | 94 | 105 |

| SBT3-M52B2 | 137 | 47 | 140 | 193 | 94 | 97 |

| SBT4-M48B1 | 167 | 50 | 150 | 197 | 97 | 105 |

| SBT4-M52B1 | 167 | 50 | 145 | 197 | 97 | 108 |

| SBT4-M52B2 | 167 | 62 | 160 | 213 | 97 | 120 |

| SBT4-M56B2 | 167 | 62 | 155 | 213 | 97 | 120 |

| SBT4-M60B2 | 167 | 62 | 150 | 213 | 97 | 124 |

| SBT4-M64B2 | 167 | 62 | 145 | 213 | 97 | 126 |

| SBT5-M64B1 | 209 | 73 | 164 | 229 | 102 | 134 |

| SBT5-M68B1 | 209 | 73 | 159 | 229 | 102 | 136 |

| SBT5-M72B1 | 209 | 73 | 156 | 229 | 102 | 139 |

| SBT5-M76B1 | 209 | 73 | 149 | 229 | 102 | 142 |

| SBT6-M76B1 | 246 | 84 | 176 | 254 | 103 | 158 |

| SBT6-M80B1 | 246 | 84 | 172 | 254 | 103 | 160 |

| SBT6-M85B1 | 246 | 84 | 169 | 254 | 103 | 162 |

| SBT6-M90B1 | 246 | 84 | 162 | 254 | 103 | 170 |

| SBT6-M95B3 | 246 | 96 | 194 | 295 | 103 | 184 |

| SBT6-M100B3 | 246 | 96 | 189 | 295 | 103 | 190 |