A well-established German manufacturer of flame arresters and tank relief valves approached us with the request to design and build a test unit for testing their pilot operated valves in Cryogenic conditions.

The reason for the test is recently introduced ISO 21013-4. This standard specifies the requirements for the design, manufacture and testing of pilot operated pressure relief valves for cryogenic service (-150 to ‑196 °C / -238 to -321 °F), i.e. for operation with cryogenic fluids in addition to operation at temperatures from ambient to cryogenic.

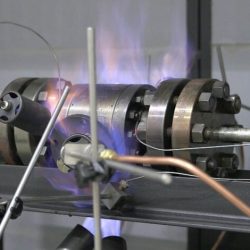

The Ventil Engineered Solutions team designed a dual-post test unit for valves in the range DN25 – 400 mm. / 1 – 16”. The unique system is completed with a fully insulated, stainless steel tank which can be filled with Liquid Nitrogen (LN2). Once released in the test tank, the LN2 warms up and the evaporation process starts. As a result the evaporating Nitrogen gas increases substantially in volume and the pressure in the tank rises. The tank is completed with a heating system to enable different vaporizing conditions and therefore work with different test criteria. This process of testing is accurately monitored by a set of sensors, measuring pressure, temperature and the LN2 level. The data coming from the sensors is processed and visualized by the Ventil Computer Registration System which also enables operation and control from a safe distance. After a series of performance tests, the valve passes the test when it successfully achieves a number of re-seating cycles.

Get in touch

Do you have questions about a certain project or you have a similar challenge in hands?

Get in touch with the Ventil Engineered Solutions team.