The quickly developing LNG market brought good times to our customer from Belfast. Their requirements for Cryogenic testing their high quality check valves, shifted from ‘one-off – type approval testing’, to testing each valve produced and assigned for these harsh operating conditions. They were looking for a more professional, safe and automated solution for testing their valves.

| Range: | Check valves 2 – 72” / Pressure Class 150 – 4500 |

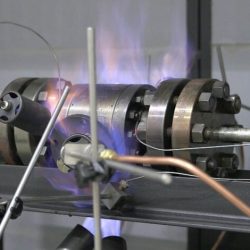

| Gas testing: | 0 – 1,500 bar / 22,500 psi. |

Challenge 1: Size matters..!

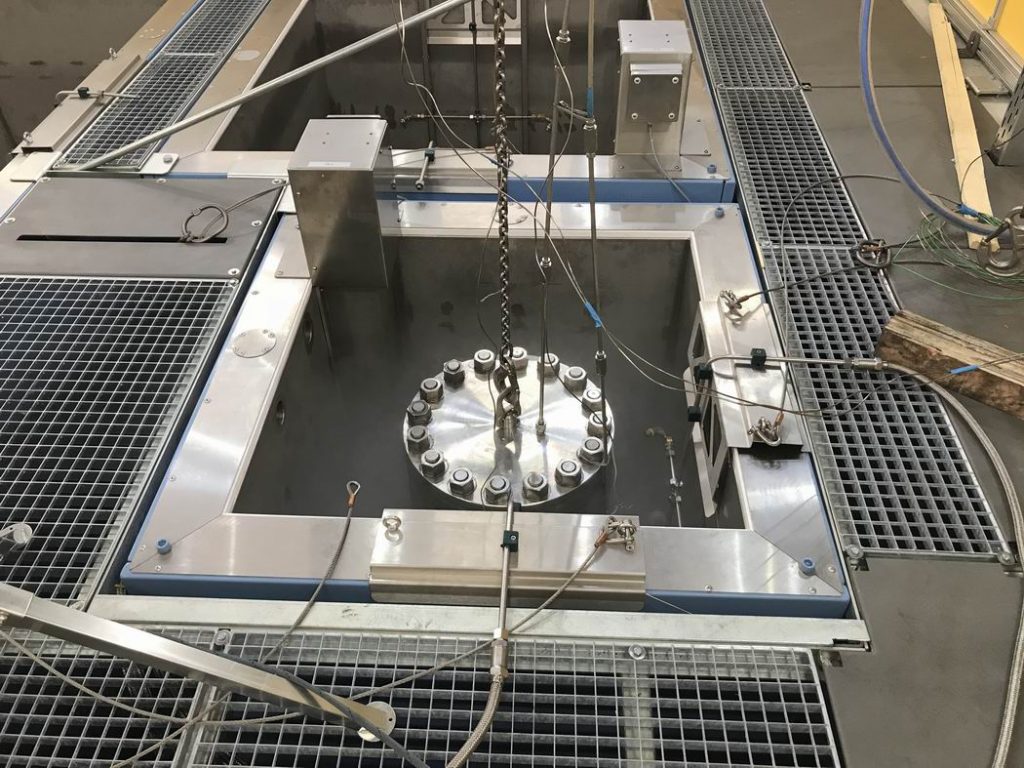

The Ventil Engineered Solution team designed a complete new test facility for testing the extended range of valves. The first challenge was the valve size and temperature. Cryogenic testing takes place at -150 to -196 °C (-238 to -321 °F) and cooling down a 72” high pressure class ‘Dual plate’ or ‘Nozzle’ type check valve requires extreme measures. To accommodate a safe and efficient cooling and testing process, 3 insulated cooling tanks and special LN2 filling system where designed. Each of the 3 tanks has a designated working range and is equipped for different LN2 cooling methods.

Cooling down valve with with Liquid Nitrogen doesn’t go without consequences. Once released in the cooling baths the evaporation process starts. Evaporating Nitrogen gas increases substantially in volume and results in Oxygen deficiency. It is odourless, colourless, and tasteless and may produce asphyxia without any sensation or prior warning. For this reason the facility is completed with a fully integrated and automatically controlled N2 gas exhaust system. On top of this, an digital Oxygen sensing system guards the test area atmosphere. The Ventil Engineered Solutions team designed a large pit for the cooling tanks and a 4 meter high, blast proof safety enclosure, surrounding the pit. This complete facility, including the exhaust system, Oxygen level sensing – safety system and access door control is secured by the electronic operating system.

Get in touch with the Ventil Engineered Solutions team.